Compressed air purification

There are a number of the air treatment systems variation, the complication of the system depend on the specific production processing features. For safe and long equipment operation, the purification of the compressed air from the particles the water and oil needed. It increase the equipment operation on compressed air (pneumatic lines, pneumatic tools, pneumatic machines), as well as on the factories where the goods quality directly depend on used compressed air. Condensate in the pipelines is very aggressive environment for the metal parts and rubber sealing and it is the main reason of the equipment failure.

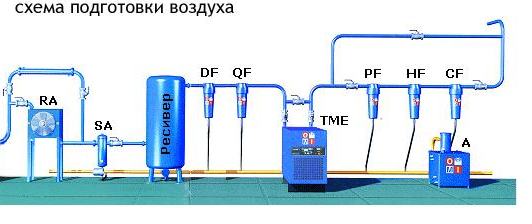

We will describe typical scheme of the air purification systems, starting with simplest.

1. Cyclone separator + filters.

Cyclone separator removes the condensed moisture and big oil particles. Usually, cyclone separators are assembly by the condensate drain. Prefilter can remove the 3 microns particles and oil particles to provide clear category up to 5 mg/m3. This system is suitable for most small enterprises like: auto repair, furniture workshops etc.

2. Cyclone separator + filter + refrigerate dryer + filters.

The separator purpose we considered in p.1, so let describe the filter function. Prefilter also used in this system, but it has to remove particles with size 1 micron to provide the clear category up to 0,5 mg/g3 (for oil). Compressed air goes to the refrigerant dryer after prior purification, where it cleared from the moisture up to the dew point +3Ñ. So the compressed air cleared by the mentioned above way is suitable for majority of the industrial enterprises. If compressed air is delivered from the new air compressor model, there is no necessity to install fine filter after refrigerant dryer.

3. Cyclone separator+series of the filter (prefilter, fine filter, intermediate filter) + dessicant dryer+ prefilter (dust filter).

After purification from the condensed moisture and oil, the compressed air goes through the series of the filters. These filters clean the air from the particles with sizes from 0,01 micron and up to oil content to0,0008 mg/m3. Then air goes to the adsorption dryer, where it clears from the residual moisture (compressed air after dryer with dew point to -70Ñ), after that going through prefilter, is cleared from the silicogel particles. Compressed air cleared by this way is used in the microelectronic, cosmetic and good production.

4. For environment protection you can use water-oil separator. Water after this device can be down into the drain, oil can be utilized.